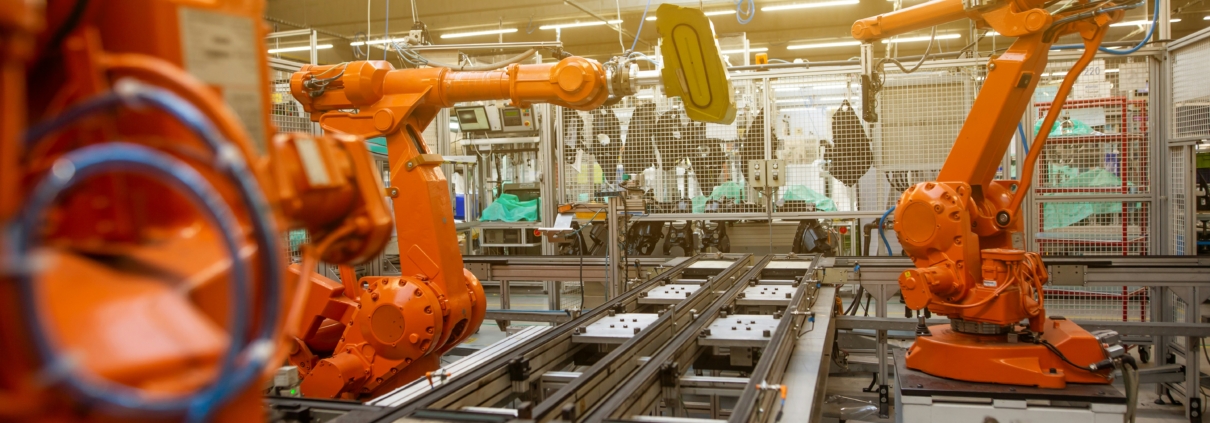

Assembly Production Lines Cleaning

As a factory owner, foreman, or industrial manager, you know that time and efficiency are money. Keeping your factory floor bustling and every machine working perfectly can be challenging, especially if you aren’t keeping up with your cleaning tasks.

Assembly production lines cleaning can’t be overlooked, as staying on track is vital to your success. Every tiny bit of rust, cracks, dirt, or grime can hamper your production process, resulting in less output and, subsequently, less profit.

The frustrating part is that most factories make cleaning excessively difficult. They use ineffective cleaning methods and faulty equipment or put it off until it becomes impossible.

We’re here to teach you a better way. This guide will show you the methods we’ve used to teach prominent Southeast Texas businesses like NuStar, AgPro, and Atacosa Wildlife Supply.

Is Assembly Production Lines Cleaning Really That Important?

But handling your assembly production lines cleaning needs will pay off massively for your short—and long-term success. With a single action, you can optimize production, maximize product quality, and avoid costly upkeep and repairs.

Compliance With Industry Standards and Regulations

Many supervisors and owners believe assembly lines cleaning is something to put off until tomorrow–right up until a pesky inspector arrives on their property.

That red tape can lead to expensive fines, recalls, or even a shutdown notice. Even a speck of dirt can be the culprit.

By regularly cleaning, you eliminate those nasty surprises. Instead of panicking, you can greet that inspector with a confident smile, knowing your facilities are in top shape.

Enhancing Product Quality Through a Clean Environment

No matter your industry, consistent assembly production lines cleaning will help boost your product quality.

Each tiny dust speck, drop of old oil or grease, or creeping spot of rust can contaminate your products. That can lead to your products breaking far earlier than expected, slightly off taste, or other potentially disastrous results.

Clean equipment avoids these issues. Fewer contaminants mean more consistent production outcomes. That difference in quality can make or break your long-term results, so don’t ignore cleaning!

Extending Equipment Lifespan With Preventative Maintenance

Assembly production lines cleaning is also vital for your recruitment. Grease, dirt, and oil buildup can corrode conveyor belts, vats, and small mechanical parts.

With how expensive your industrial machinery is, you can’t take this lightly. Regular cleaning will help you catch potential minor repairs before they become costly total replacements. Every dollar and bit of time you spend cleaning your equipment now will save you ten times that amount down the line.

Creating a Safe Work Environment for Employees and Visitors

Your assembly lines see plenty of foot traffic between clients, vendors, investors, and employees.

Creating a tidy space means fewer accidents, cheaper insurance premiums, and a workforce that feels motivated and cared for. That means no more slippery floors, tripping hazards, or dusty air.

What is the Best Way to Clean Assembly Production Lines?

Prioritizing assembly production lines cleaning is essential.

Most businesses make the mistake of choosing the wrong methods. Only one method has the speed, safety, and effectiveness to do the job quickly without disrupting production: pressure washing.

Challenges of Traditional Cleaning Methods

Consider the typical cleaning methods for production facilities.

There’s manual scrubbing, which is just a nightmare. Making your employees use a mop, broom, and sponge is asking them to get on the wrong side. To make things worse, it can take hours, or even days, all for poor results that only serve to leech your labor budget.

Chemical treatments are effective but very dangerous. They can directly lead to recalls, damage to your equipment, and health issues for your staff.

With either of these options, you’re looking at plenty of downtime and poor results.

Advantages of Pressure Washing for Assembly Lines

Thankfully, there’s a method that is fast, effective, and safe: pressure washing.

Power washers are lightning-fast, allowing you to clear entire rooms in minutes, not hours. The power behind their jet streams can lift even the toughest stains from surfaces. Grime, oil, rust, grease–no matter the substance, there’s a pressure washer able to handle it.

Complementing Pressure Washing With Manual and Automated Methods

While pressure washing commercial buildings is an excellent primary cleaning method, you can complement it with a few other pieces of equipment.

Manual cleaning can be helpful in hard-to-reach nooks and crannies, especially on delicate surfaces. Additionally, automated cleaners can be attached or integrated with your production lines for consistent cleaning.

Establishing a Regular Cleaning Schedule for Optimal Results

As you learn to pressure wash, it is essential to find a cleaning schedule that works for your operations.

You’ll need to set aside time. Start by mapping out your entire facility and identifying high-traffic areas that accumulate stains quickly.

For daily cleaning, you’ll rely on your automatic cleaners and quick manual wipe-downs that you can assign to employees. Weekly deep cleans with your pressure washer are a great practice to adopt to get started.

Pressure washing is the best commercial floor cleaning technique. When creating your schedule, it’s wise to also schedule other vital tasks in your factory.

Warehouse pressure washing, cleaning cooling towers, pressure washing factory floors, cleaning inside silos, and vehicle fleet pressure washing should also be added to your list to ensure your entire property is in peak condition.

Sourcing Pressure Washing Equipment, Detergent, and Accessories for the Most Productive Process

You’ll need the best commercial pressure washer and assorted equipment to get your production facility in peak condition.

While many types of pressure washers are available, one brand stands out above the rest: Hotsy.

Hotsy has over 50 years of reputation with industrial organizations worldwide, thanks to their premium-quality machines and biodegradable detergents.

Ideal PSI and GPM Ranges

PSI (pounds per square inch) and GPM (gallons per minute) are among the most vital metrics when shopping. They note the force and volume of water in your machine’s stream.

You’ll need 1500 PSI for very delicate machinery. But most tasks in your facility, including stubborn stains like grease, oil, and rust, require 2500-3500 PSI.

Aim for at least 4 GPM to give you the cleaning speed you need.

Is a Gas or Electric Model Better?

Choosing between gas vs electric pressure washers depends on the layout of your facility.

Both are suitably powerful, though gas machines have a slight edge. The difference is in mobility and emissions.

Gas models are better for partially outdoors and well-ventilated spaces since they don’t need to be plugged in. However, electric machines are generally preferred indoors, as they are low-noise and zero-emission.

Hot vs Cold Water Units

Water temperature is another vital decision. Choosing between hot water vs cold water pressure washers is relatively straightforward. Cold water models are cheaper but generally have less power. Heated models are better suited for the usual stains on an assembly line, like rust and oil.

Degreasers and Industrial Cleaners

If you’re just firing up your power washer and blasting away, you’re missing a key step. By adding soap to a pressure washer, you can eliminate stains in a fraction of the time.

Hotsy’s line of biodegradable soaps is just what you need to restore your assembly line to peak condition.

We have a few different recommendations based on the surfaces you’re working with:

- Hotsy Ripper I & II: Ripper I & II are powerful, do-it-all degreasers ideal for industrial settings.

- Hotsy Breakthrough: The go-to soap for nearly every surface.

- Hotsy Verde All-Purpose: An eco-friendly, all-natural blend.

- Hotsy Citrus Clean: A natural degreaser using d-limonene for a great-smelling finish.

- Hotsy Yellow Fever: Safe for use on aluminum, clears carbon deposits and grease.

- Hotsy Shop Floor Cleaner: Perfect for petroleum-based stains

- Hotsy Brown: An extra-caustic blend for stubborn stains. Avoid metal surfaces.

Essential Accessories for Efficiency

The right accessories can help minimize manual scrubbing. Hotsy makes the best pressure washer accessories, including surface cleaners, extension wands, and turbo nozzles.

Consider your nozzle tips as well. Wide angles are perfect for clearing large areas at once, while narrow nozzles help you tackle tough stains with a concentrated spray. Hotsy’s hose reels can also help you switch quickly between angles, giving you flexibility while cleaning.

There’s plenty of gear to buy for pressure washing, but all of it is a worthy investment. With your shopping list complete, the only thing left is to find a reliable retailer.

Get in Touch With Hotsy of Houston

If you want to eliminate the stress and guesswork of upgrading your cleaning gear, look no further than our team!

At Hotsy of Houston, you’ll find the best equipment for cleaning your assembly line. We’re the only place to find Hotsy brand commercial pressure washers in Houston, giving you access to the best machines in the world.

Our friendly and experienced team has the know-how to make the process a breeze. We’ll show you what to look for in a pressure washer, from PSI and GPM to accessories. You’ll also have our guidance on how to rent a power washer, how to use a pressure washer, and what kind of soap to use in a pressure washer.

We offer sales and commercial pressure washer rentals in Houston to fit your budget. That includes our selection of pressure washer trailers in Houston, saving you the worry of creating a homemade pressure washer trailer yourself.

Long after your purchase, we’ll still be by your side. We’re the #1 home for commercial pressure washer repair in Houston, including non-Hotsy models. We offer affordable pressure washer repair costs, maintenance for pressure washers, and speedy service to help you avoid downtime.

Tips on Cleaning Assembly Production Lines Effectively

Once you’ve found your machine and the best soap for your pressure washer, it’s time to learn how the cleaning process works. Put on protective gear, such as goggles, gloves, and non-slip boots to wear while pressure washing, and you’re ready to start!

Finding the Optimal Time to Clean Your Facility

Timing is crucial to your success. You can’t start cleaning in the middle of a production run.

Look for natural lulls in your schedule. During shift changes or after hours would be ideal.

You can set aside a maintenance window if you don’t want to overlap labor costs, but it may lead to decreased production, nullifying any savings.

Removing Loose Debris and Protecting Sensitive Equipment

Before you start blasting away, remove anything that can become a projectile. That means loose tools, leftover parts, or any significant bits of trash.

Cover all sensitive equipment, including electrical outlets, sensors, and biological objects.

Starting With High-Traffic and High-Debris Zones

As you begin, set aside the high-traffic areas first. This will provide two benefits: It lets you tackle the most challenging problem first and gives you plenty of wiggle room. If that area takes longer than you planned for, you’ll still achieve a cleaner, more efficient facility overall.

The Role of Surface Pre-Treatments

You should apply detergent to each surface before you start washing. Letting it soak in for 10 to 15 minutes will break down those stubborn, encrusted stains, making them easier to remove.

Don’t let it sit too long, or it will accumulate residue.

Rinsing From Top to Bottom in Overlapping Patterns

Use gravity as your friend while washing. Sweep your wand from top to bottom with overlapping motions, allowing water to flow downwards.

Keep your wand at least 12 inches from the surface to avoid excessive damage.

We recommend starting with your wide nozzle and slowly narrowing it down, which gives you more time to hit those stubborn stains.

Post-Cleaning Inspection and Final Rinse

When the main washing is complete, rinse down all of the surfaces. As they begin to dry naturally, check for any missed spots. You may need to restart the process on specific problem areas from the top.

When that’s done, you can rest easy and celebrate. Just find a cool, dry place for pressure washer storage, and you’ll be all set until next week’s cleaning.

Parting Thoughts on Assembly Production Lines Cleaning

Tidying up your assembly line is critical to your facility’s success and output. With the right equipment, you can take care of stains in minutes, giving you extra room in your schedule.

Our team at Hotsy of Houston can help you get set up with all the gear you need. From commercial cold water pressure washers in Houston to pressure washer detergent and degreasers, our team will walk you through everything.

We’ve worked with organizations across industries, helping them understand pressure washing business start-up costs, pressure washing farm equipment, cleaning grease traps, cleaning commercial vent hoods, pressure washing commercial solar panels, quoting pressure washing jobs, restaurant pressure washing, and pressure washing parking lots.

If you’re ready to experience the cleaning power yourself, stop by the #1 home for commercial hot water pressure washer in Houston or talk to our team by phone!